Aluminum Casting Explained: Key Truths and Insights for Market Professionals

Aluminum casting functions as an essential procedure in modern-day manufacturing, forming components across various sectors. Its varied methods, such as sand and die casting, deal with various manufacturing needs. The special homes of aluminum alloys enhance their applicability, yet tests remain in preserving quality and efficiency. Recognizing these aspects is crucial for industry specialists. What are the most recent developments and finest techniques that can additionally enhance this procedure?

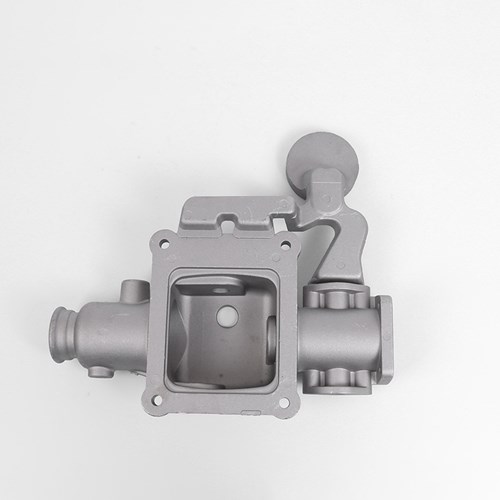

Summary of Aluminum Casting Processes

Secret aspects of aluminum casting processes consist of the preparation of mold and mildews, which might be made from sand, steel, or ceramic materials, relying on the intended use. Additionally, temperature control is vital to assure appropriate melting and solidification of aluminum.

The casting process permits for detailed layouts and can attain high degrees of dimensional accuracy. Once cooled, the spreadings may undertake ending up operations such as machining or surface therapy to satisfy details performance standards. Generally, aluminum casting serves as a versatile production method, successfully satisfying the varied needs of various sectors.

Types of Aluminum Casting Techniques

In the domain of aluminum casting, numerous methods are utilized to achieve various results. Sand casting strategies supply adaptability and cost-effectiveness for complicated forms, while die casting procedures provide high accuracy and performance for automation. Comprehending these approaches is necessary for choosing the appropriate method based upon job needs.

Sand Casting Strategies

Sand casting strategies stand for an essential technique in aluminum casting, where sand is used as a mold and mildew material to shape liquified steel. This procedure entails creating a pattern from the preferred part, which is then positioned in a sand mix to form a mold. The sand is compressed around the pattern, and after elimination, it creates a dental caries in the form of the component. Molten aluminum is put right into this tooth cavity, permitting it to strengthen and cool down. One considerable advantage of sand casting is its adaptability; it can fit large components and intricate forms. Additionally, the materials used are relatively economical, making it an obtainable choice for various manufacturing applications in the aluminum market.

Die Casting Processes

Die casting procedures are a famous method for shaping aluminum elements, making use of high-pressure strategies to require liquified metal into exactly crafted mold and mildews. This process is especially preferred for its capacity to generate complex shapes with limited resistances and a smooth coating. There are two main kinds of die casting: hot chamber and chilly chamber. Hot chamber die casting is suitable for steels with reduced melting factors, allowing for faster production rates. Alternatively, chilly chamber die casting is excellent for higher melting factor steels, needing a different melting heating system. Both methods enhance efficiency and decrease material waste, making them important in automotive, aerospace, and consumer products sectors. Understanding these processes aids specialists select the most ideal technique for their details applications.

Material Quality of Aluminum Alloys

Toughness and Longevity

Strength and longevity are crucial attributes of aluminum alloys that make them appropriate for numerous casting applications. These materials exhibit a desirable strength-to-weight ratio, enabling the creation of light-weight yet robust components. When it come to tensile toughness, certain aluminum alloys can be engineered to withstand significant loads without warping. This home is particularly crucial in industries such as aerospace and automobile, where efficiency and safety are paramount. Additionally, aluminum alloys frequently keep their mechanical residential or commercial properties under diverse temperature problems, guaranteeing constant efficiency. The innate ductility of these alloys additionally enables reliable shaping during the casting procedure, making it simpler to create complex geometries. In general, additional info the stamina and resilience of aluminum alloys contribute substantially to their extensive use in innovative applications.

Rust Resistance Characteristics

While aluminum alloys are treasured for their toughness and light-weight properties, their corrosion resistance is one more important feature that improves their suitability for different applications. Aluminum naturally develops a safety oxide layer when exposed to wetness, which helps to prevent more oxidation. This integral residential or commercial property makes aluminum alloys especially beneficial in settings vulnerable to rust, such as commercial and aquatic setups. In addition, different alloy compositions can affect resistance levels, with specific alloys specifically engineered to improve this particular. Therapies like anodizing can even more improve rust resistance by thickening the oxide layer. Subsequently, recognizing the rust resistance of aluminum alloys is important for industry experts when picking materials for projects requiring sturdiness and longevity in tough settings.

Benefits of Aluminum Casting in Production

Aluminum casting deals many benefits in production, making it a preferred option for various markets. One considerable advantage is its light-weight nature, which adds to lowered transportation expenses and enhanced power effectiveness in final product. Furthermore, aluminum's exceptional thermal and electric conductivity enhances functionality in applications calling for warmth dissipation or electric transmission.

The product's ability to be cast right into detailed forms enables design adaptability, decreasing the demand for added machining procedures. On top of that, aluminum casting exhibits premium rust resistance, bring about longer product life expectancies and lower maintenance prices.

Common Applications of Aluminum Castings

The adaptability of aluminum casting enables its extensive usage throughout various markets. Common applications include vehicle parts, where lightweight and corrosion-resistant elements, such as engine blocks and transmission real estates, enhance car performance. In the aerospace sector, aluminum castings are made use of for structural parts, providing toughness without adding significant weight.

In addition, the electrical sector take advantage of aluminum castings in making rooms and heat sinks, where thermal conductivity is vital. The consumer goods field also integrates aluminum castings in products like kitchenware, furniture, and attractive products, incorporating aesthetics with performance.

The building and construction sector uses aluminum spreadings for building aspects, window frameworks, and components, which provide resilience and layout versatility. Generally, the diverse applications of aluminum spreadings emphasize their significance in contemporary production, adding to innovations in efficiency and product design throughout several fields.

Innovations and Technological Developments

As sectors remain to advance, developments in aluminum casting technology are changing production procedures and item abilities. Advancements in 3D printing and additive manufacturing have made it possible for the production of complicated geometries that were previously difficult to achieve with standard methods. These technologies enable quick prototyping, lowering preparations and expenses.

Furthermore, enhancements in mold layout and materials have actually enhanced the casting process by enhancing performance and lowering waste. The integration of wise manufacturing techniques, such as IoT devices and real-time data analytics, enables far better monitoring and optimization of manufacturing specifications, leading to higher high quality results.

Moreover, growths in aluminum alloys offer enhanced toughness, rust resistance, and light-weight residential properties, accommodating the growing needs in vehicle and aerospace sectors. Collectively, these technologies are not just boosting performance but also satisfying the strenuous requirements of modern-day design applications.

Best Practices for Quality Assurance in Aluminum Casting

Making certain top quality outcomes in aluminum casting needs adherence to ideal techniques that incorporate various read the full info here phases of the manufacturing procedure. Detailed product examination is necessary to validate the top quality of aluminum alloys made use of, as pollutants can greatly affect the last item. Executing accurate melting and putting strategies lessens problems; maintaining ideal temperature levels stops oxidation and promotes uniformity.

Moreover, mold and mildew style plays a vital role; making use of computer-aided style (CAD) can enhance precision and minimize human error. Routine monitoring of the cooling procedure is vital to prevent warping and contraction. Furthermore, utilizing non-destructive screening methods, such as ultrasonic or X-ray assessments, helps recognize interior flaws without harming the components.

Finally, developing a feedback loophole with operators and designers promotes constant improvement, making sure that high quality control measures progress together with technological innovations. By adhering to these finest techniques, manufacturers can improve the dependability and efficiency of aluminum spreadings.

Regularly Asked Concerns

What Are the Ecological Influences of Aluminum Casting?

The environmental impacts of aluminum casting include considerable power intake, greenhouse gas emissions, and potential water contamination from shop procedures. Additionally, bauxite mining for aluminum ore can cause environment devastation and soil degradation.

Exactly How Does Aluminum Casting Contrast to Various Other Steel Casting Procedures?

Aluminum casting typically supplies benefits in lightweight components and corrosion resistance compared to various other processes, such as iron or steel casting, which may give better strength but lead to much heavier and less corrosion-resistant products. - Aluminum Foundry

What Are Usual Flaws in Aluminum Castings and Their Reasons?

Typical problems in aluminum castings consist of porosity, contraction, and incorporations. Causes frequently stem from improper pouring methods, insufficient mold style, or contamination of the molten metal, impacting the final item's stability and performance.

What Safety Precautions Should Be Taken Throughout Aluminum Casting?

During aluminum casting, vital safety preventative measures consist of wearing safety equipment, making certain correct air flow, maintaining a clean work space, taking care of liquified metal with treatment, and adhering to read review well-known procedures to reduce risks of burns, breathing dangers, and accidents.

How Can I Boost the Effectiveness of My Aluminum Casting Operations?

To improve efficiency in aluminum casting procedures, one ought to optimize mold and mildew design, streamline product handling, employ automated procedures, carry out regular upkeep on devices, and purchase staff member training to improve abilities and performance.

Different methods exist, aluminum casting incorporates a number of key processes that provide to different applications and needs. Secret components of aluminum casting procedures consist of the prep work of mold and mildews, which might be made from sand, metal, or ceramic products, depending on the planned use. Sand casting methods stand for an essential approach in aluminum casting, where sand is used as a mold product to form molten metal. As industries continue to evolve, technologies in aluminum casting innovation are changing production processes and item capabilities. Making certain top notch outputs in aluminum casting needs adherence to ideal methods that encompass different phases of the production process.